CHP-Based Heat Supply for the Municipal District Heating Network

“Thermal Storage Facility – Stadtwerke Frankfurt (Oder)”

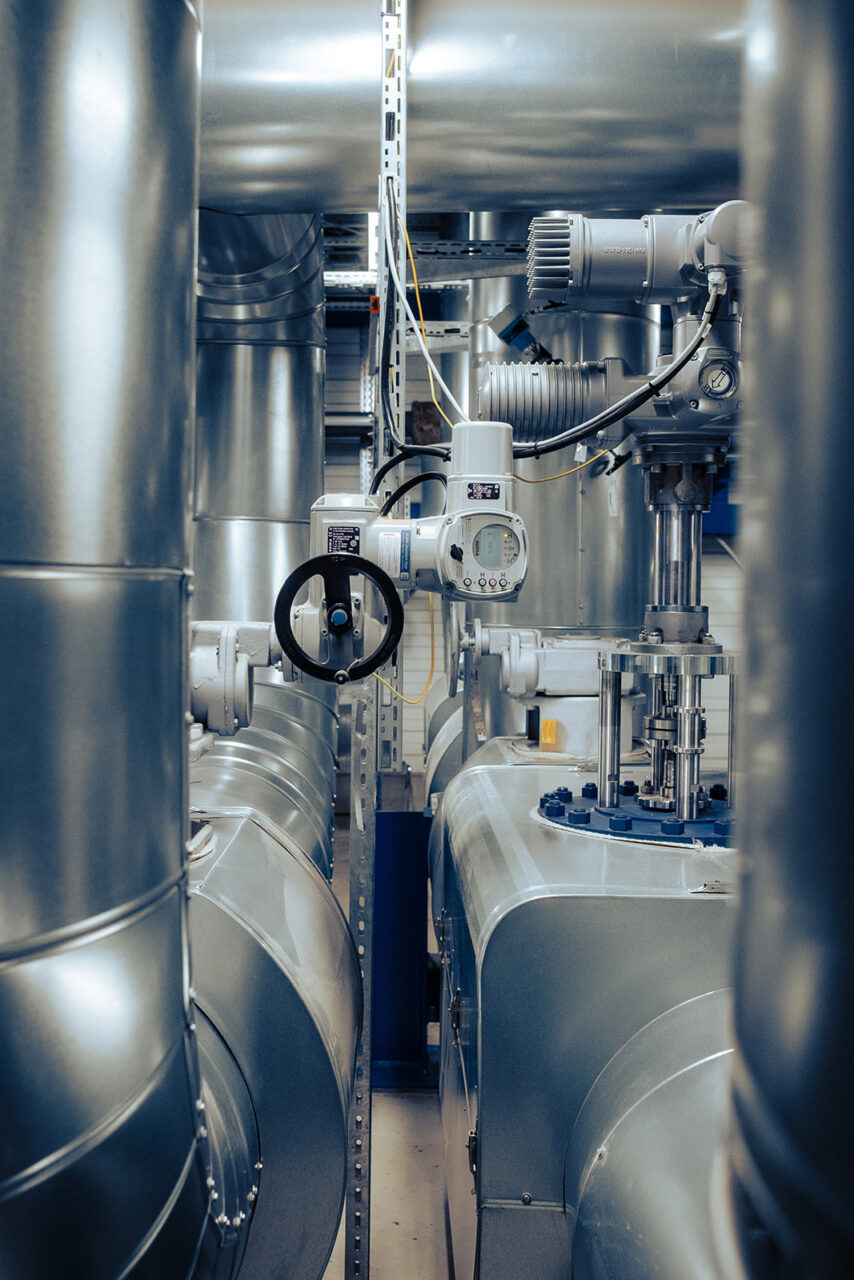

Stadtwerke Frankfurt (Oder) operates several combined heat and power plants (CHP) at the site of its cogeneration plant to ensure the supply of heat to the city’s district heating network.

Client: Stadtwerke Frankfurt (Oder) GmbH

Stakeholders: Waldemar Pruss Armaturenfabrik GmbH

AUMA Riester GmbH & Co. KG

Project period: 2024 – 2025

Location: Frankfurt (Oder)

Special features:

- Thermal Storage for Stabilizing the District Heating Network

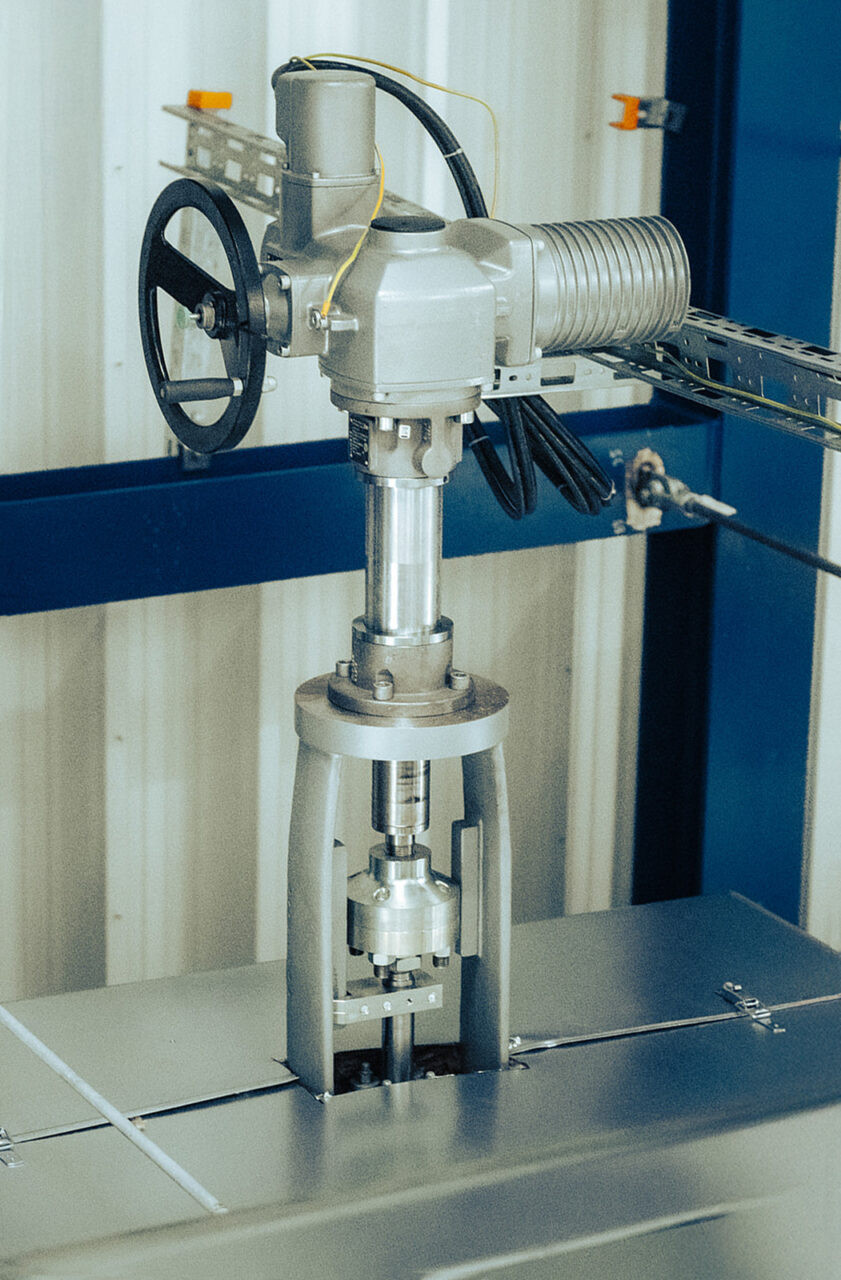

- Optimization of Control Valves for Atmospheric Storage Operation

- Cavitation Identified and Eliminated as the Root Cause

- Three-Stage Pressure Reduction for Stable Control

- Significantly Improved Operational Reliability and Service Life

Contact person NOPA:

Grid Stabilization Through Thermal Energy Storage

Intermediate Storage of Waste Heat to Decouple Electricity and Heat Demand

In order to make a contribution to grid stabilisation at the same time, a thermal energy storage (TES) facility was built to temporarily store the waste heat from the CHP plants when the electricity grid demand is high but heat consumption in the district heating network is low.

Due to its size, the TES facility operates without pressure. For loading, the network pressure must therefore be relieved via control valves – a critical function that determines the efficiency and reliability of the entire system.

Task definition

Improving Control Performance and Reliable Integration of the Thermal Storage System

After a short period of operation, it became apparent that the valves used by the system installer at the time were inadequately designed for this task. The operator noticed massive pressure fluctuations and unsteady operation of the valves. The control units were not able to reliably maintain their set values.

The goal was therefore clearly defined: The control quality during operation had to be significantly improved in order to smoothly integrate the TES facility into the overall system and reliably secure both the grid stability and the heat supply.

The central task for NOPA was to identify the causes of the inadequate control and, on this basis, to develop a technically optimised, durable and economical solution for the customer.

Planning

Cavitation Identified as the Primary Cause of Unstable Control Behavior

Stadtwerke Frankfurt (Oder) approached NOPA directly with the problem.

The first step involved the facts being recorded in detail – including the process conditions, the operating points and the technical design of the valves used.

Based on this analysis, NOPA’s engineering team developed the following hypothesis: The unsteady control was due to cavitation in the valve seat. This phenomenon, in which local pressure reductions below the steam pressure create steam bubbles that collapse abruptly when the pressure subsequently rises, leads to unstable flows, pressure fluctuations, increased noise and heavy wear and tear.

To test the theory, the existing valves were inspected. The suspicion was confirmed: clear traces of cavitation on the control valves proved the inadequate design of the existing solution.

On-site implementation

Replacement of Existing Valves and Successful Commissioning by NOPA

Based on the test results, NOPA developed an optimised design for the control valves. Instead of a simple pressure reduction, a three-stage pressure reduction was planned. This distributes the entire pressure drop over several stages, prevents the steam pressure in the valve from falling below the required level and significantly reduces the risk of cavitation.

NOPA’s service department dismantled the existing valves, installed the new control valves and carried out the complete commissioning. Meanwhile, the close collaboration between the engineering, sales and service departments ensured that technical findings, product adaptations and practical implementation were seamlessly integrated.

Project result

Significantly Improved Control Performance, Reduced Wear, and Long-Term Reliable Operation

Alle unzureichend ausgelegten Ventile im Regelkreis wurden durch All inadequately designed valves in the control circuit were replaced with optimised control valves. The result: considerably improved control quality, significantly lower pressure fluctuations and reliable operation of the TES facility.

The three-stage pressure reduction effectively prevents cavitation, resulting in minimal wear and tear and therefore a significantly longer service life for the fittings used.

The project underlines the strength of the interaction between the three NOPA business areas:

- Engineering analysed the problem and developed the solution;

- Sales worked with the supplier to develop the right valve design;

- Service implemented the measures on site.

This not only increased the operational reliability of the plant, but also strengthened the trust which Stadtwerke Frankfurt (Oder) had in NOPA as a long-term partner.

More references from the category

Energy

| Industry Category | Energie |

| Project period | 2007 - 2008 |

| Client | Vattenfall AG, KSC Anlagenbau GmbH |

| Location | Boxberg |

| Details | Also involved in this project: Crane, ARI Armaturen Albert Richter GmbH & Co KG., Klinger, VAG GmbH, Drehmo GmbH |

| Industry Category | Energie |

| Project period | 2009 - 2010 |

| Client | BHR Hochdruck Rohrleitungsbau GmbH |

| Location | Braunschweig |

| Details | Also involved in this project: SIPOS Aktorik GmbH, ARI Armaturen Albert Richter GmbH & Co KG., KLINGER Fluid Control GmbH, Böhmer GmbH, Leser GmbH & Co.KG. |

| Partner |   |