Sewage sludge utilization plant

“Bitterfeld-Wolfen”

The sewage sludge utilization plant KVA serves the thermal utilization of municipal sewage sludge. It is thus an essential component of the nationwide strategy for phosphorus recovery. As a building block of DNA, the element phosphorus is a prerequisite for all life on earth and cannot be substituted. In order to close the phosphorus cycle in Germany, the German government enacted phosphorus recovery via the recycling of sewage sludge AbfKlärV) in October 2017. The Bitterfeld sewage sludge recycling plant can dispose of approximately 260,000 tons of sewage sludge per year. For thermal utilization, the sludge is first dried and then incinerated. In the future, phosphorus can be recovered from the remaining phosphorus-containing ash in a further process and the cycle closed.

“We may be able to replace coal with nuclear power, wood with plastic, meat with yeast, and kindness with isolation, – however, for phosphorus there is no substitute.”

Quote Isaac Asimov (1920 to 1992)

At the same time, the recycling plant operates completely self-sufficiently in terms of energy, because both the heat required for pre-drying the sewage sludge and the electrical energy required for operating the plant are obtained from the process itself. In addition, even up to 8,000mwh of regenerative electricity can be fed out per year.

Client: KÜTTNER martin technology GmbH

Project period: 2020 – 2021

Location: Bitterfeld-Wolfen

Special features:

- complete equipment supplier for KVA Bitterfeld-Wolfen.

- completely self-sufficient waste disposal plant

Contact person NOPA::

Robert Schmidt

Sewage sludge recycling

Sustainable phosphorus recovery

NOPA was already involved in the tender planning of the plant by the general planner PME Projektmanagement & Engineering GmbH and defined the necessary quality characteristics of the industrial valves already in this early phase.

In doing so, it was essential to use durable and innovative products that are precisely matched to the respective requirements. NOPA does not only consider the initial equipment of a plant, but as an active service partner has the entire life cycle of each valve in mind. The operator of the plant, KSR GmbH and its parent company, pd energy GmbH, already appreciate this competence at its other sites.

The cooperation between NOPA and the general planner PME started 15 years ago, during a joint project. For two waste incineration plants in Stavenhagen and Bitterfeld, the decision to source selected fittings fell on the specialists from Eisenhüttenstadt. As a result of this successful cooperation, paths once again converged at KVA, enabling the partnership to be deepened even further.

Planning with NOPA expertise

Development of a quality standard for valves

During the planning phase, the process engineering parameters of the plant were defined, and NOPA naturally supported PME GmbH with its expertise in defining the requirements for the valves derived from these parameters. Together, a general quality standard for valves was developed, which defines the quality characteristics of each valve in each application. Thus, in addition to NOPA’s expertise, the operator’s many years of operating experience also flowed into this quality standard.

NOPA as supplier for kva Bitterfeld-Wolfen

Cooperation with pme, ksr and Küttner Martin Technologies

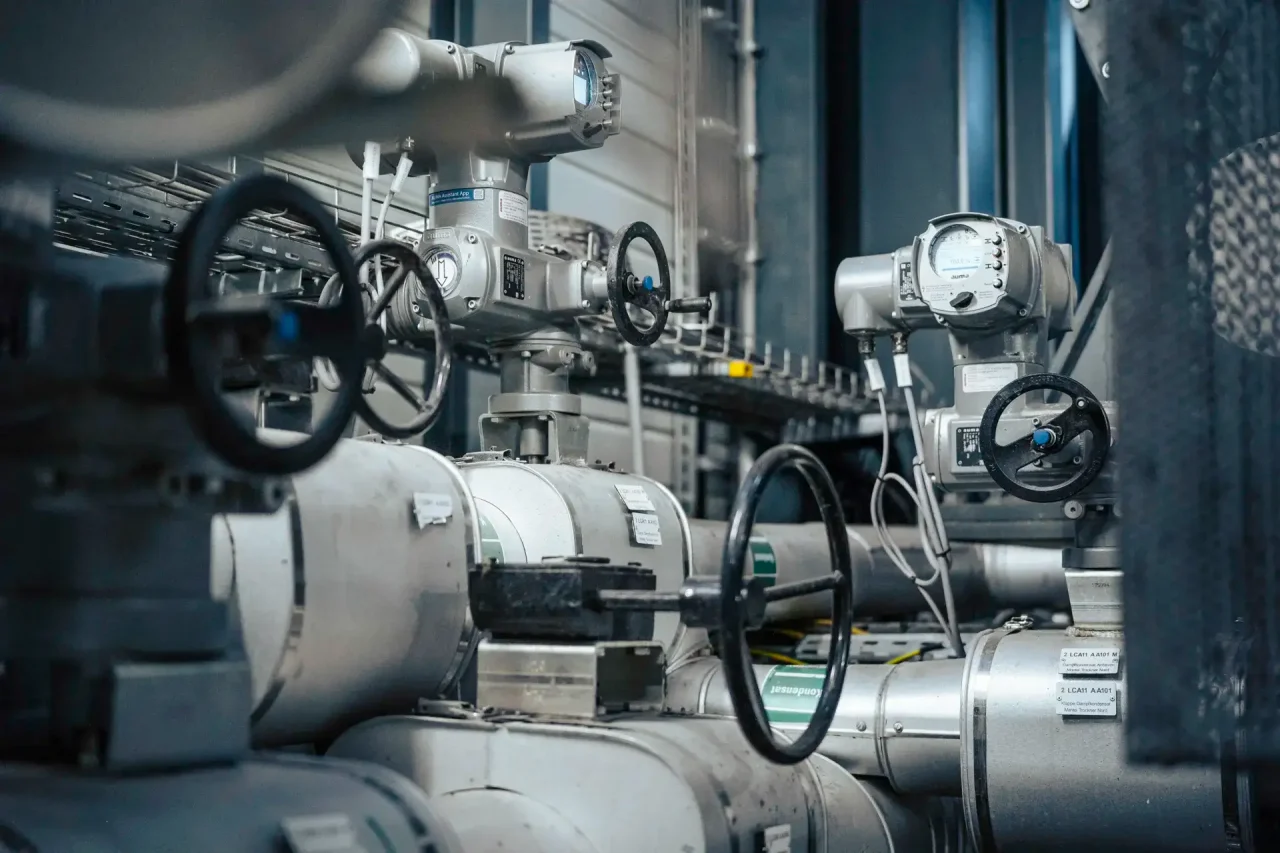

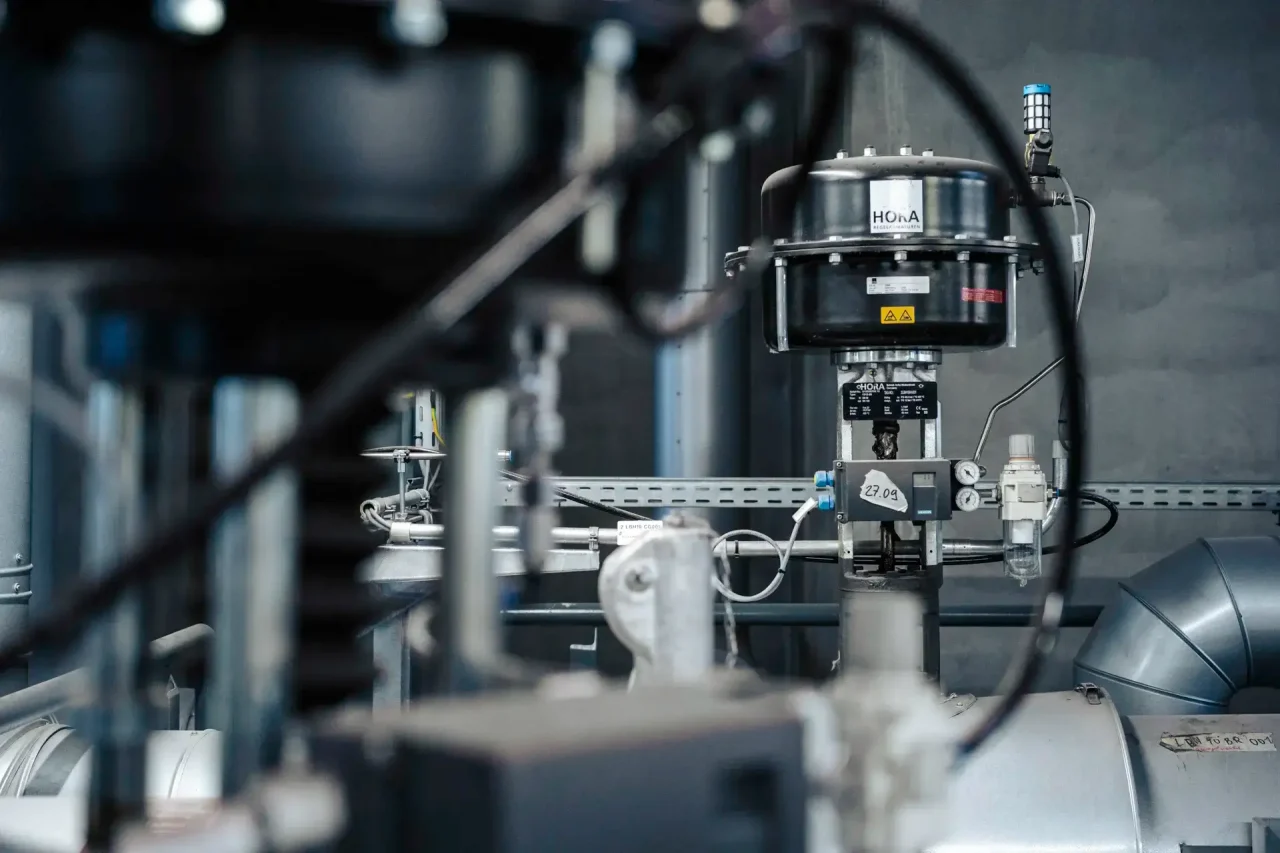

During the subsequent realization of the plant, NOPA was able to convince with its offer as a supplier for the scope of valves and became almost the complete supplier for KVA Bitterfeld-wolfen. NOPA was in constant contact with the process engineering general contractor, KÜTTNER martin technologies GmbH, when it came to the detailed design of the valves. NOPA’s scope of supply included control valves, steam-converting valves, safety valves, ball valves, gate valves, butterfly valves, and globe valves. The valves were equipped with pneumatic or electric actuators, depending on the requirements.

Cooperation took place with the general planner PME Projektmanagement & Engineering GmbH, the operator KSR Klärschlamm Bitterfeld-wolfen GmbH, and with the general contractor KÜTTNER martin technologies GmbH and its subcontractors Würz GmbH, Howden turbo GmbH, and AEL Apparatebau GmbH.

Successful project

NOPA and partners complete commissioning with success

From tender planning in 2017 to final commissioning in 2022, NOPA acted for its various partners in this project. The commissioning of the plant was successfully completed in the second quarter of 2022.

This project was characterized by a cooperative partnership and the years of experience in the valve sector that NOPA and the operator were able to bring to bear during the tendering process for the plant. This goal-oriented and technically experienced approach could also be continued with the plant constructor, KÜTTNER martin technology GmbH. This comprehensive cooperation of all parties involved in every phase of the project finally resulted in a plant equipment that enables a smooth and precise plant operation.

For safety and reliability

NOPA takes over service

We organize maintenance and servicing in close coordination with the operator of the system. We offer individual solutions and customized service plans that are tailored to the specific requirements and needs of the plant.

When servicing industrial valves in sewage sludge treatment plants, special requirements have to be observed; in particular, ensuring a high level of operational safety is a priority for disposal plants. In order to meet our high quality standards, maintenance work is carried out exclusively by trained personnel who have the necessary skills, knowledge and experience.

Always a little better

Optimization of maintenance processes

Regular service and maintenance is typically organized through maintenance schedules based on manufacturer recommendations, operating conditions and other factors. These plans are created and managed manually or using maintenance management software. We use digital technologies and data analytics to better predict maintenance needs, optimize maintenance schedules and plan maintenance work more effectively.

Sensors on valves collect data to react to problems at an early stage, while digital tools are used to plan and monitor maintenance work. By continuously collecting and analyzing data, we can identify bottlenecks and weak points in the processes and increase the effectiveness and efficiency of maintenance processes.

Sustainable and safe

Equipped for the future with NOPA

Regular maintenance contributes to the sustainability and environmental friendliness of the sewage sludge recycling plant, as it improves the operational safety and efficiency of the plant and reduces unnecessary emissions and waste. It can also increase the service life of the entire plant.

Vision:

Once a year, the waste incineration plant in Bitterfeld undergoes a scheduled inspection shutdown lasting 2-3 weeks, during which the entire plant is put through its paces. The operator mainly inspects the combustion chamber and the heat exchanger surfaces, which are naturally subject to greater wear. In order to make optimum use of this existing time window and also to ensure that the financial outlay for our client is even and predictable, a maintenance cycle for the complete scope of fittings is therefore generally 3 years.