RDF Power Plant for Progroup’s PM3

“Paper Machine in Sandersdorf-Brehna”

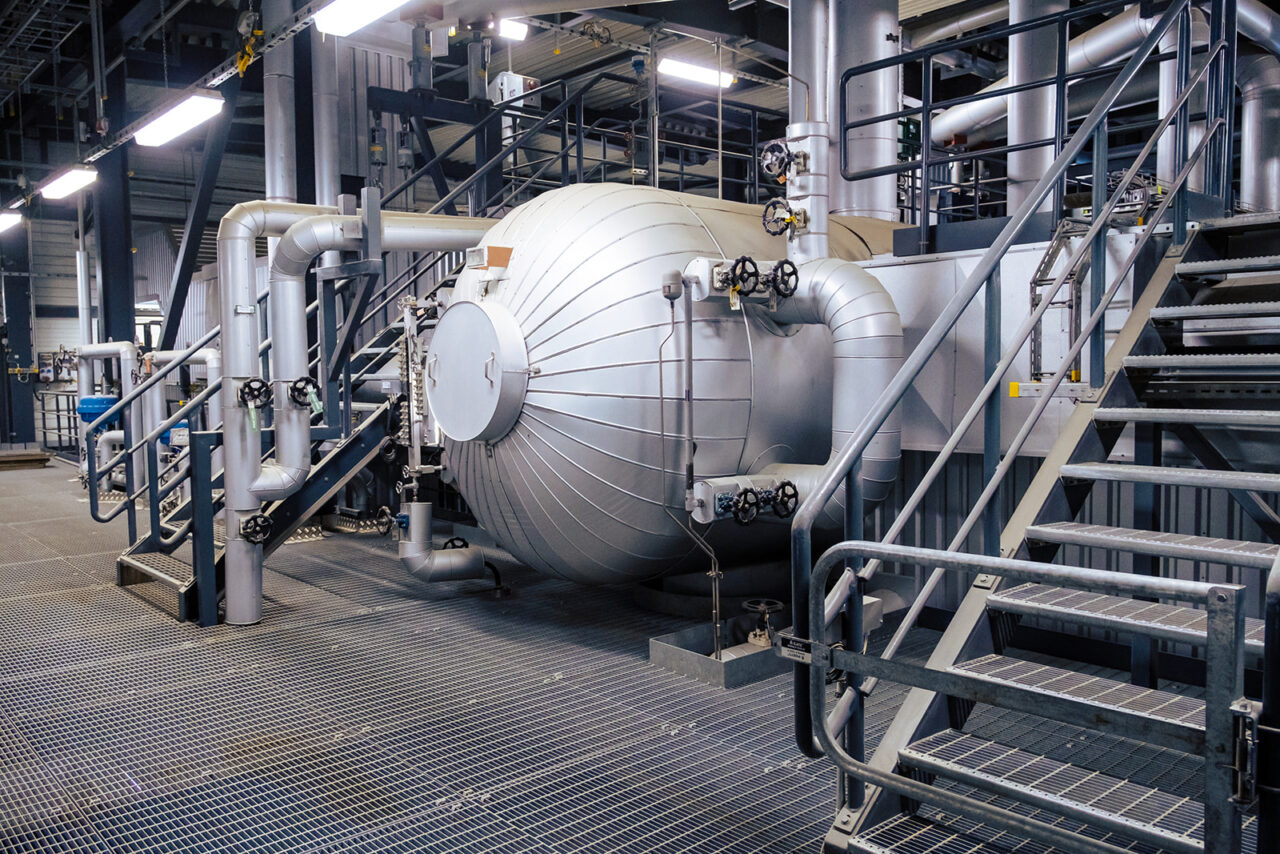

The refuse-derived fuel (RDF) power plant at the Sandersdorf-Brehna site is a central component for the sustainable energy supply of Progroup AG’s Paper Machine 3 (PM3). PM3 is one of the largest and most modern paper factories in the world and produces containerboard and corrugated board for the packaging industry.

Client: Progroup AG

ROBUR Industriemontagen GmbH

SPIE Industriemontagen GmbH

Project period: 2023 – 2024

Location: Sandersdorf-Brehna

Special features:

- Two HDUs

- Customised commissioning concept

- Optimised safety valves and silencers

- Flexible installation adjustments

- Fast response times

Contact person NOPA:

Robert Schmidt

Sandersdorf-Brehna

refuse-derived fuel (RDF) power plant

To ensure the high and continuous demand for process steam and electricity, Progroup AG relies on its own power plant, which is operated with refuse-derived fuels. This makes the energy supply not only independent, but also particularly efficient.

The task of the RDF power plant is to provide a stable water-steam cycle that ensures both electricity production via the turbine and direct steam extraction for paper production. This project represents an important step towards security of supply, economic efficiency and sustainability at the site.

Task definition

Secure and flexible energy supply for paper production

For the operation of Paper Machine 3 (PM3), a power supply was required that ensured maximum availability and flexibility. The continuous demand for process steam required a precise design of the water-steam cycle in order to reliably cover both the base load and peak loads.

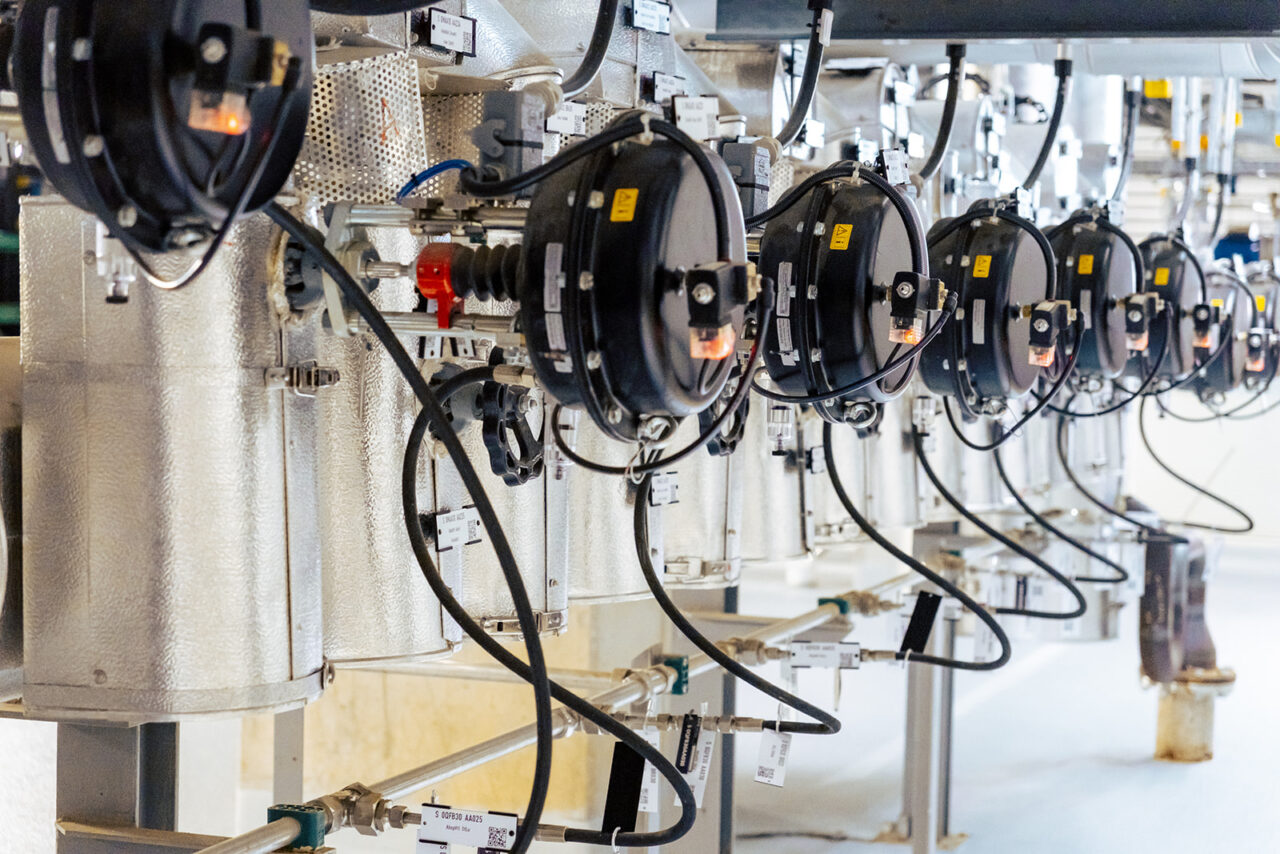

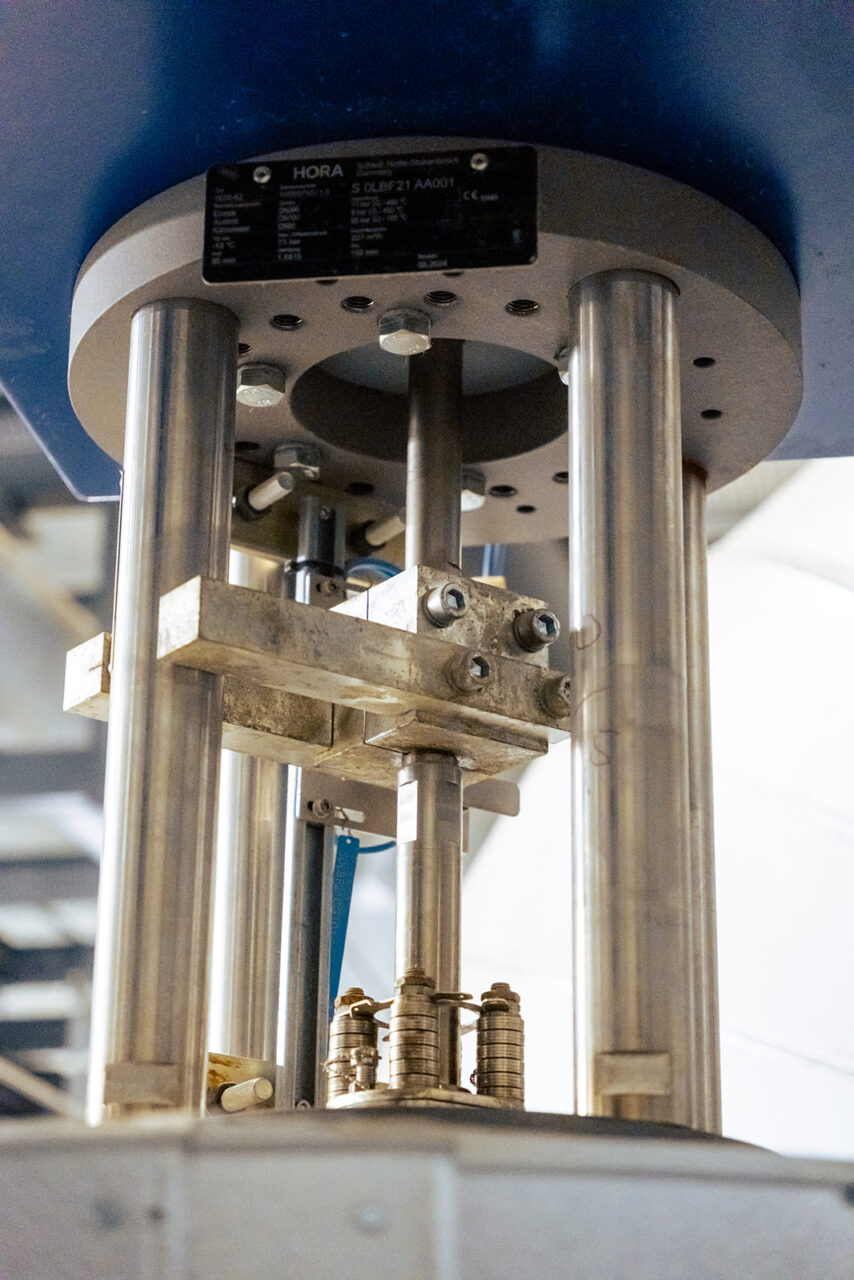

The core task for NOPA was the planning and supply of high-pressure steam-converting valves (HPVs). In the event of a malfunction, these take over the functions of the turbine, independently safeguard the steam flow and enable additional steam to be supplied at maximum load operation. At the same time, they improve the control quality in the partial load range and create leeway so that the turbine can react flexibly to grid requirements.

In addition to the high-pressure steam-converting valves, NOPA was also able to win the valve batch from plant manufacturer SPIE Industriemontagen GmbH. This meant that NOPA ultimately acted as a complete supplier of the fittings.

For NOPA, the project offered the opportunity to further expand its long-standing partnership with Progroup AG. The company was already in demand as a supplier and service partner for PM2 in Eisenhüttenstadt and PM3, which went into operation in 2020. The new power plant has further strengthened its role in the Bitterfeld region.

Planning

Development and selection of tailor-made solutions

The central technical requirement was a stable water-steam cycle that reliably supplies the paper machine. Two HDVs were installed to ensure reliability:

- one high-pressure steam-converting valve that takes over the function of the turbine in the event of a turbine failure and continues to supply steam independently;

- a second, smaller HDV that covers peak loads as well as improving the control quality in low-load operation.

A key aspect of the planning was the comprehensive design of the safety valves and silencers. Through optimisation, it was possible to make the construction method significantly more efficient, reduce costs and minimise roof loads.

In addition, a special commissioning concept was developed: Pickling and rinsing inserts protected the HDVs during the cleaning and passivation processes of the pipelines. This prevented dirt or chemicals from affecting the valves.

On-site implementation

Flexible adjustments and fast response times

Thanks to its proximity to the Bitterfeld-Wolfen service branch, NOPA was able to respond to additional requirements at short notice and thus meet the tight schedule.

Despite intensive planning, some adjustments, such as the alignment of fittings and drives, could only be finalised during installation on site. However, the rapid availability of NOPA technicians meant that these challenges could be met without delay.

All work steps were comprehensively documented and checked for compliance with the agreed quality standards.

Project result

Maximum security of supply and long-term efficiency

The project was successfully completed on schedule. The installed HDVs ensure a reliable and flexible energy supply for the paper machine. Load fluctuations can be balanced out efficiently, while at the same time the availability of the power plant remains at the highest level.

For NOPA, the project not only resulted in a successful technical implementation, but also a deepening of the long-standing collaboration with Progroup AG. In addition, valuable contacts were established with the project partners Eproplan GmbH and SPIE Industriemontagen GmbH.

In the long term, the new RDF power plant will contribute to greater operational reliability, energy efficiency and process stability – and underlines NOPA’s role as a reliable partner for demanding industrial projects.

More references from the category

Paper

| Industry Category | Papier |

| Project period | 2019 - 2021 |

| Client | Hamburger Rieger GmbH |

| Location | Spremberg |

| Details | Also involved in this project: Müller Quadax GmbH, RIFOX - Spezialarmaturen Hans Richter GmbH, KLINGER Fluid Control GmbH, RITAG Ritterhuder Armaturen GmbH & Co. Armaturenwerk KG |

| Partner |   |

| Industry Category | Papier |

| Project period | 2007 - 2008 |

| Client | Propapier Burg Gmbh, EnBW Energy Solutions GmbH |

| Location | Burg |

| Partner |  |